Grinding wheels

Generalities

The grinding wheels are hard crystal grinding tools with a lot of cutting edges. These crystals are held together by a bond, forming products with different shapes and dimensions.

Based on the nature of bond, Carbochim produce and sell the following groups of grinding wheels:

- vitrified bonded grinding wheels

- bakelite bonded grinding wheels

- magnesite bonded grinding wheels

- elastic bonded grinding wheels

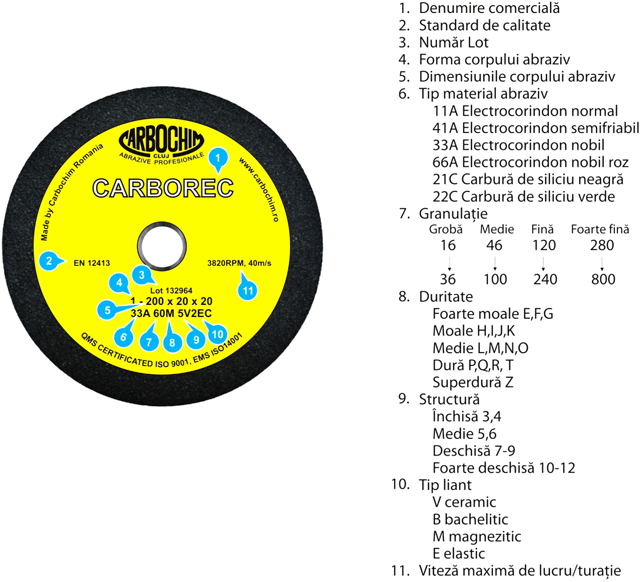

Marking

The grinding wheels are high precision tools used for grinding and finishing of a wide range of materials. The quality of the surface obtained during grinding proces depends on following factors:

- grinding wheel - characterised by the abrasive material, grit size, hardness, structure, bond type.

- grinding procces parameters - passing speed, in-going feed, peripheral work speed,

- grinding machine - type, rate of ware, adjustements

Abrasive material type

Abrasive material type is selected based on the nature and the characteristics of the processed material:

-

Brown fused aluminium oxide - 11A

High hardness and toughness fused aliminium oxide containing 95-97%AI203. Recommended for low alloyed steel grinding on high power machines.

-

Semi friable fused aluminium oxide - 41A

Less hardness, toughness and more friable fused aluminium oxide than the brown one, containing 98% AI203 Recommended for heat sensitive and hardened steel in precision grinding.

-

White fused aluminium oxide - 33A

High hardness and brittle fused aluminium oxide containing min. 99% AI203. These characteristics grant high self-sharpening features for grinding wheels and high protection of grinding surfaces.

Recommended for mild steel, hardened steel, stainless steel, cast iron precise grinding and sharpening

-

Mono-crystalline fused aluminium oxide - 31A

Abrasive material with min. 99%AI203, obtained by special proceeding.

Each mono-crystaline fused aluminium oxide grain makes up a single crystal with a lot of edges which adhere strongly to bond bridges, that gives superior qualities to the grinding wheel from the point of view of efficiency and work precision. Recommended for rapid and tools steel processing, for high alloyed steels and thermo sensible steel rectifying that require removal of large material additions or even the full cutting (processing feed 2-3mm/pass)

-

Pink fused aluminium oxide - 66A

High hardness and toughness fused aluminium oxide superior than the white one containing 99% AI203 and 0,25% Cr203 Recommended for high-alloyed steel, stainless steel, cast iron grinding.

It is used for manufacturing of grinding wheels for internal grinding, mounted points for steel and cast iron grinding.

-

Electroruby - 77A

High hardness and toughness fused aluminium oxide containing 99% AI203 and 2,5% Cr203 Recommended for low temperature of high-alloyed steel grinding.

-

Black silicon carbide - 21C

Hard abrasive material containing 97%SiC.

Recommended for cast iron, brass, bronze, aluminum and low resistence materials grinding.

-

Green silicon carbide - 22C

High hardness and more friable abrasive material than the black silicon carbide, containing 99%SiC. Recommended for hard and very hard metals, cast iron, ceramics, glass, stone and concrete grinding

Generalities

-

Grit size

Grit size is defined as the medium size of the abrasive grains, marked with numbers according to the FEPA F series standard.

In order to select the proper grinding wheels the following rules must be considered:

- coarse grits size - recommended for processes where a high stock removal rates is required:

- big pieces;

- soft materials ;

- large contact areas;

- fine grits size - recommended for finishing processes:

- hard and fragile materials,

- small contact surface

Based on piece shapes, we recommend:

- coarse grit size for plane surfaces

- fine grit size for profiled surfaces

- coarse grits size - recommended for processes where a high stock removal rates is required:

-

Hardness

Hardness is defined as the bond strength against the tendency of external forces to remove grains from the grinding wheel during grinding processes.

Generally, grinding wheels hardness is marked with letters .

Based on hardness we divide grinding wheel in the fallowing categories:

- Very soft: E, F, G

- Soft: H, I, J, K

- Medium: L, M, N, O

- Hard: P, Q, R,T

- Extra hard :Z

Select the hardness of the grinding wheel considering following rules:

- high hardness is recommended for:

- soft materials

- small contact area

- roughing, deburring and cutting operations

- low hardness is recommended for:

- hard materials;

- large contact area.

-

Structure

Structure is defined as the percentage ratio between abrasive materials, bond and pores volume. The structure of Carbochim wheels are designated by numbers:

- very open : 10,11,12

- open: 7,8,9 -medium: 5,6

- closed: 3,4 -very closed: 1,2

Carbochim's standard structure for vitrified grinding wheels is 5, respectively 4 for bakelite bonded grinding wheels.

In order to select the proper grinding wheel the following rules must be considered:

-closed structures - recommended for:

- profiled surfaces.

- medium structures- recommended for:

- universal grinding and tools sharpening

-open structures- recommended for:

- heat sensitive material grinding.

- rubber and plastic materials grinding

-

Bond

Carbochim use different types of bonds to manufacture grinding wheels which are designed as follow:

- V- vitrified bond

- B- bakelie bond

- M- magnesite bond

- E elastic bond

According to Carbochim's know-how these bond's symbols are followed by numbers indicating bonds subtypes suitable for different applications.

Select bonds type considering the following rules:

- vitrified bond - recommended for sharpening and grinding operations.

- bakelite bond - recommended for roughing, deburring and finishing operations proceeded at high working speed.

- magnesite bond - recommended for heat sensitive materials and large contact areas grinding.

- elastic bond - recommended for finishing and super-finishing operations.

-

Peripheral work speed

Peripheral work speed is an important parameter of grinding wheels that directly influence grinding quality.

Grinding wheels are used at peripheral work speeds between 20-80 m/s as follow:

- Vitrified bonded grinding wheels: 32, 35,40, 63m/s

- Backelite bonded grinding wheels: 32,45, 50, 63, 80m/s

- Magnesite bonded grinding wheels: 16, 20m/s

- Elastic bonded grinding wheels: 20m/s

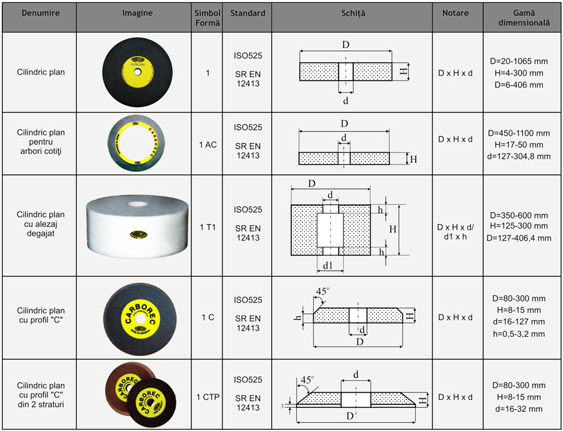

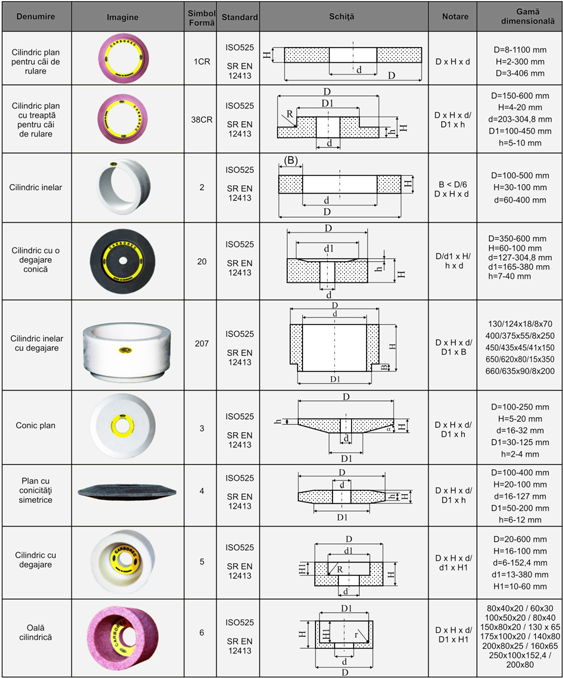

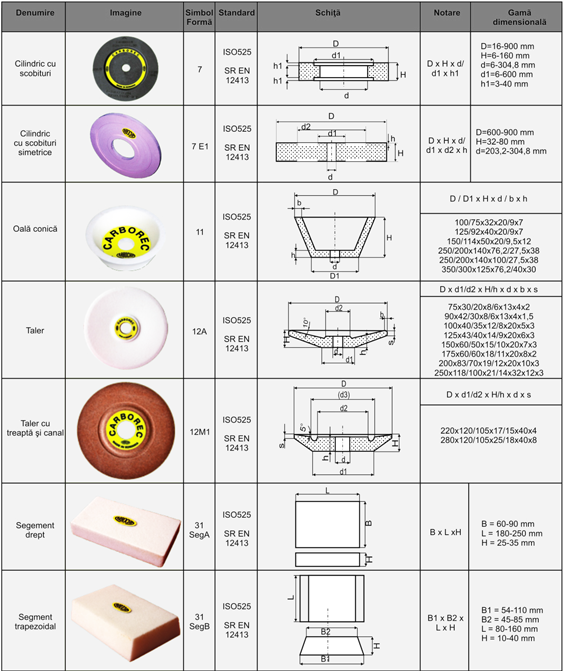

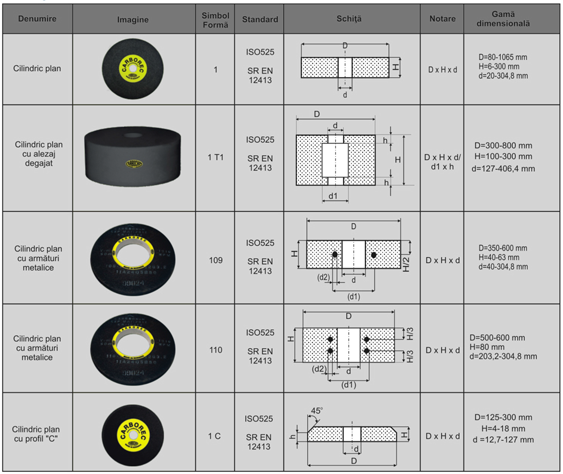

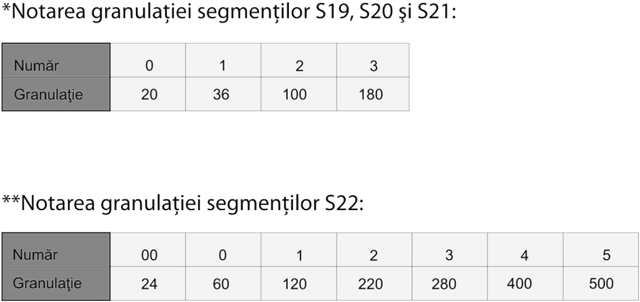

Vitrified bonded grinding wheels - shapes and dimensions

Vitrified bonded grinding wheels are shaped products made of abrasive grains bonded with ceramic adhesive. They are the grinding wheels most widely used in industry, encountered in all types of rectifying operations. By combining the characteristics offered by the utilized abrasive material, the bond's properties and the porosity of the grinding wheel, any demands in the rectifying operations can be met.

Within these operations, an optimal balance is required between the profile of the grinding wheel and its self-sharpening, characteristics determined by the vitrified or sintered structure of the ceramic bond. Ceramic bonded grinding wheels have a natural porosity that can be artificially increased using pore agents. The porous structure allows an optimal cooling of the rectified pieces and the easy removal of the chipped material.

Vitrified bonded grinding wheels are recommended for precision rectifying of alloy steels, heat- sensitive pieces, hardened pieces and tool sharpening operations. When the rectifying process requires high precision and high surface quality, a vitrified bonded grinding wheel must be used. For internal rectifications in the bearing industry, sulfur-impregnated vitrified bonded grinding wheels are used to obtain a good surface and to counteract intense heat generating.

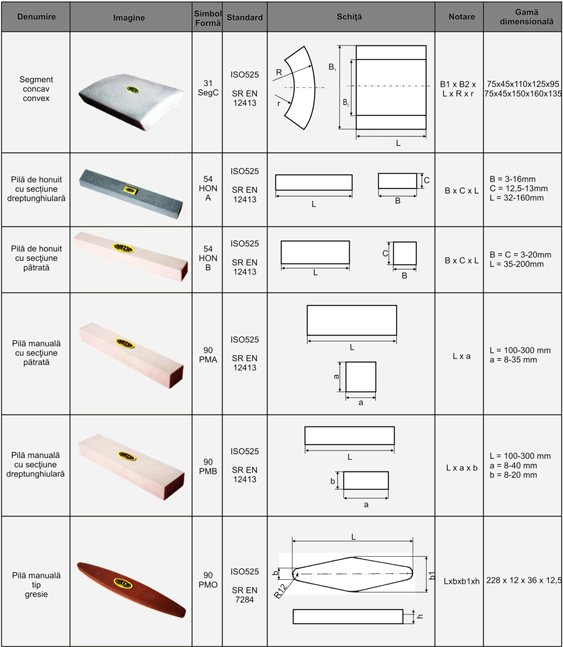

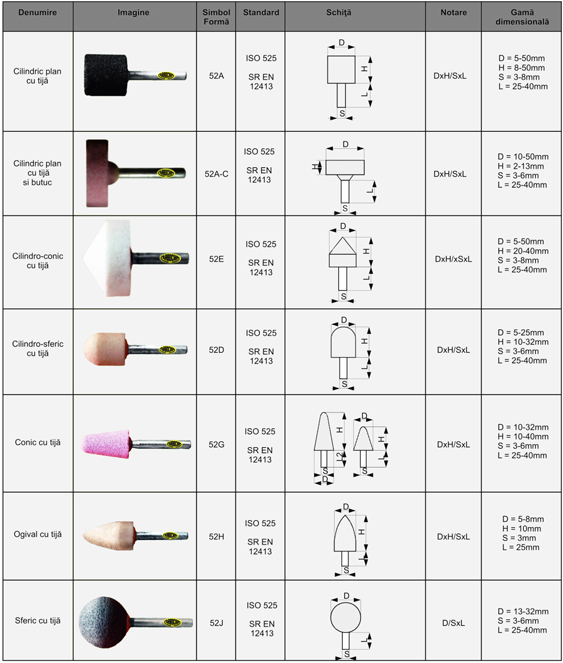

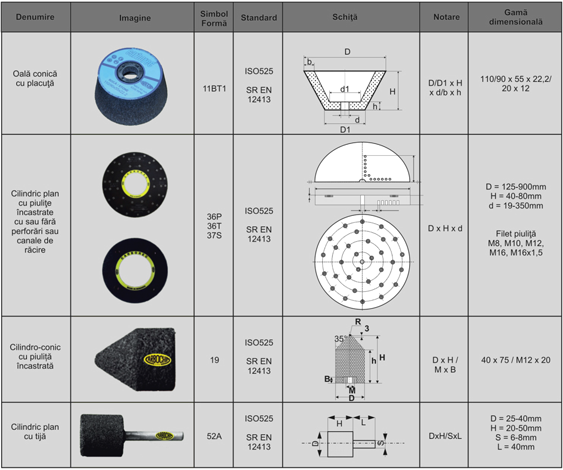

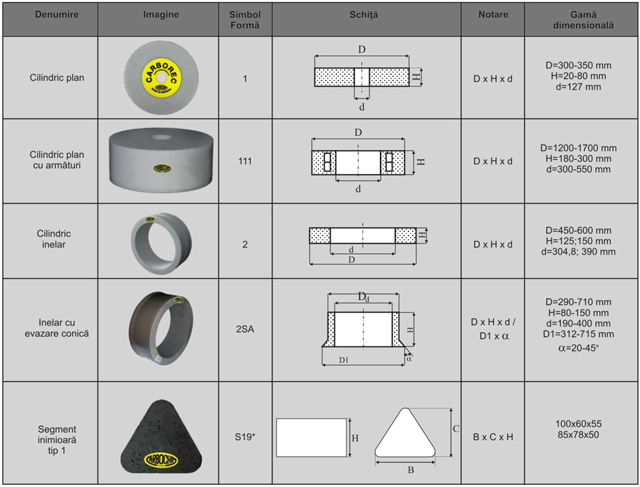

Shapes and dimensions

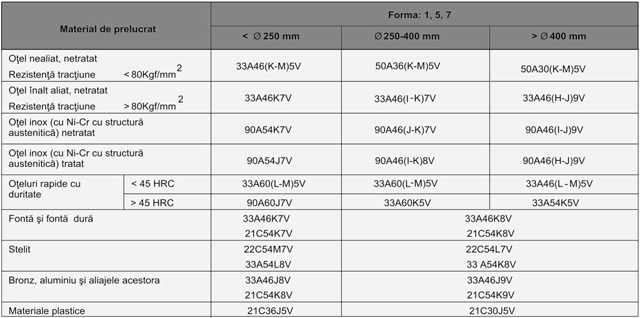

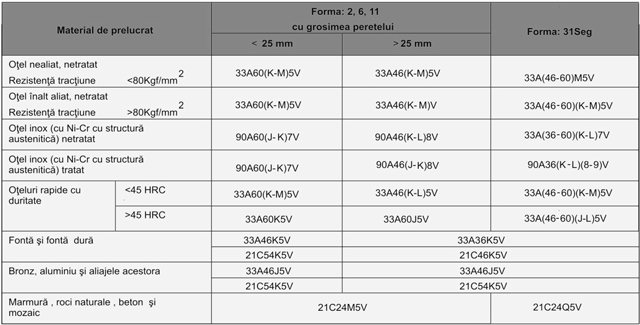

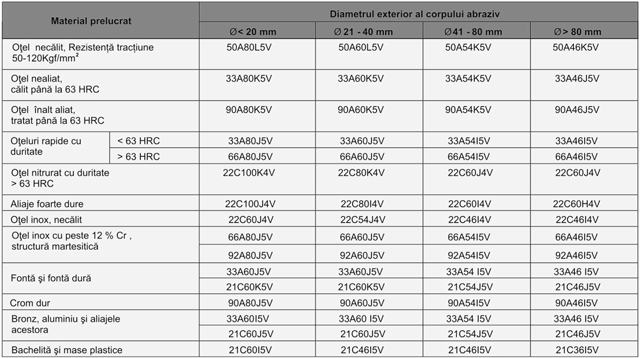

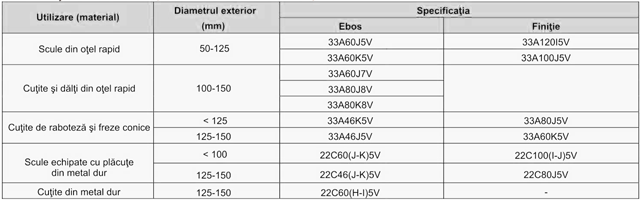

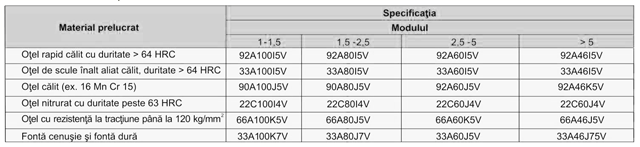

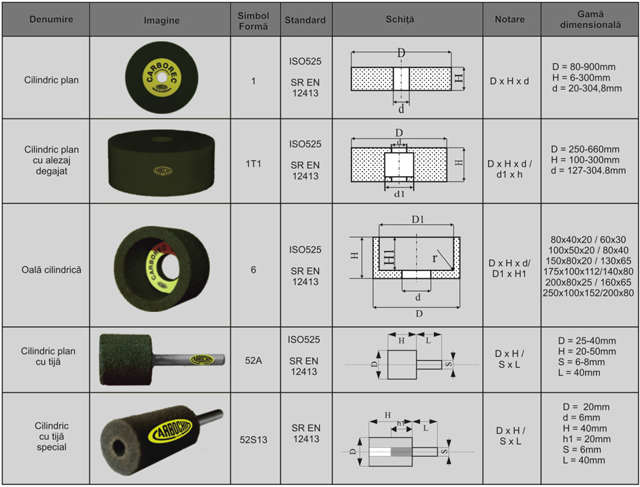

Vitrified bonded grinding wheels - general recommendations

Carbochim's vitrified bonded grinding wheels general recommendations

Recommendations are based on usual grinding parameters:

- stock removal rate -max.0,5 mm,

- peripheral work speed -40 m/s

- feed -max. 0,2 mm

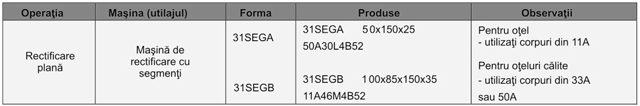

1. Surface grinding

-use 1, 5, 7, 2, 6,11, 31 SegA, 31 SegB and 31 SegC shapes grinding wheels

2. External cylindrical grinding

-use 1, 5, 7 and 1T1 shapes grinding wheels

3. Internal cylindrical grinding

-use 1, 5 and 7 shapes grinding wheels

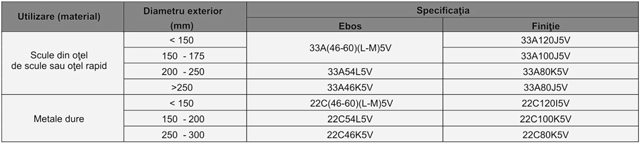

4. Tool sharpening

-use 1 and 5 shapes grinding wheels

-use 1C and 1CTP shapes grinding wheels

-use 3 and 12 shapes grinding wheels

-use 6 and 11 shapes grinding wheels

5. Special grinding

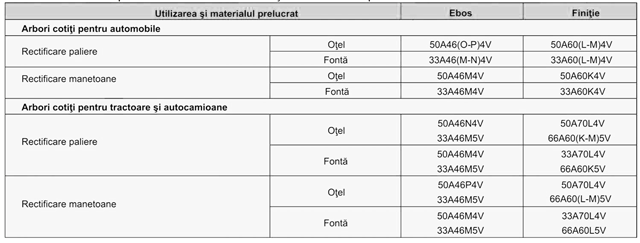

5.1 Crankshaft grinding

-use 1AC and 7E1 shapes grinding wheels on 46-40 m/s peripheral work speed

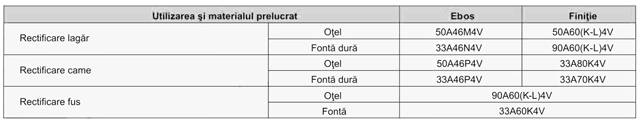

5.2 Camshaft grinding

-use 1 AC shape grinding wheels

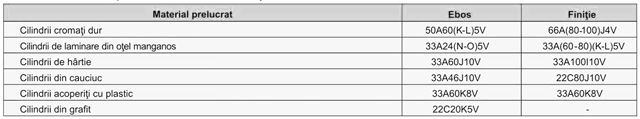

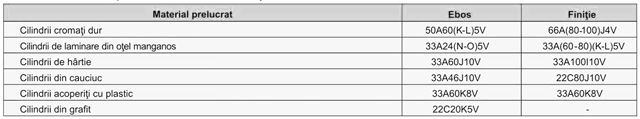

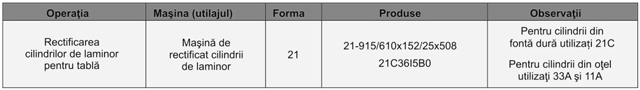

5.3 Rolls grinding

-use 1 and 1AC shapes grinding wheels

5.4 Gear wheels

5.4.1. Gear wheel grinding using MAAG system machines

-use 12M1 shape grinding wheels

5.4.2 Gear wheels grinding using NILES system

-use 3 and 4 shapes grinding wheels

5.5 Superfinishing

-use 1, 90PMA and 90PMB shapes grinding wheels

5.6 Honning

-use 54HONA and 54HONB shapes grindings stones

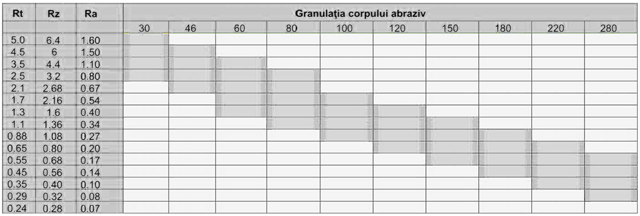

Grit size choosing recommendation for ceramic bonded wheels depending on the roughness needed after the grinding process:

Note:

- The general recommendations are adequated for: (V=40 m/s; materials=all; medium grinding condition, grinding depth/pass - max. 0,1-0,2 mm )

- For special applications please send all data regarding grinding process to technical department of CARBOCHIM S.A.

- For Rz roughness it is used the Rz=4xRa formula

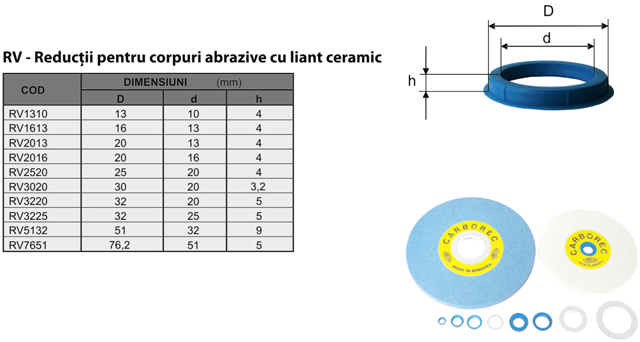

Bore adapters

Dedicated to adapt the grinding wheels bores to the axles of the grinding machines.

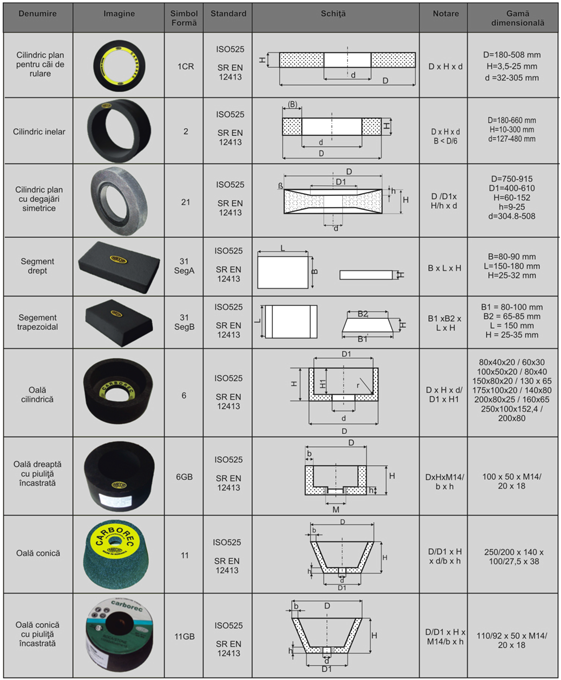

Bakelite bonded grinding wheels - shapes and dimensions

Bakelite bonded grinding wheels are shaped products made of abrasive grains included in an organic bond based on reticulated phenol resins.The bond contains fillers that help to cool the contact area between the grinding wheel and the processed piece, as well as to remove splinters. Some grinding wheels contain materials which form artificial pores. According to the application requirements and in order to increase the peripheral speed resistance, bakelite bonded grinding wheels may contain metallic reinforcements, glass fiber inserts orfixing nuts.

Bakelite bonded grinding wheels are suitable for grinding processes requiring a high stock removal rate.

Although in many applications bakelite bonded grinding wheels are complementary to vitrified bonded grinding wheels, there are applications where productivity is an important parameter, like spring and baring industry, where they represent the only alternative.

Shapes and dimensions

Other shapes and dimensions can be manufactured on custom request.

Other shapes and dimensions can be manufactured on custom request.

Other shapes and dimensions can be manufactured on custom request.

Bakelite bonded grinding wheels - general recommendations

Carbochim's bakelite bonded grinding wheels general recommendations

1. Rectifying

1.1 Surface grinding

-use 31SegA and 31SegB shapes grinding segments

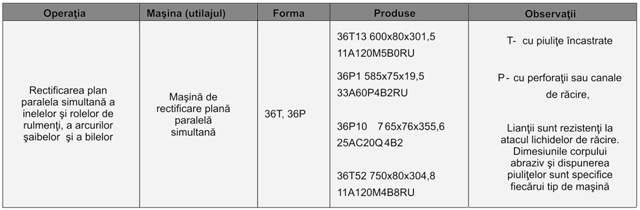

1.2 Both side grinding

-use 36T and 36P shapes grinding wheels

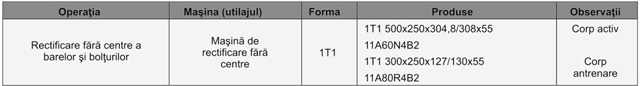

1.3 Centerless grinding for bolts and rodes

-use 1T1 shape grinding wheels

1.4 Rolls grinding

-use 21 shape grinding wheels

2. Grinding

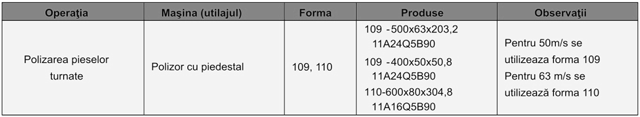

2.1 Cast pieces grinding

-use 109 and 110 shapes grinding wheels

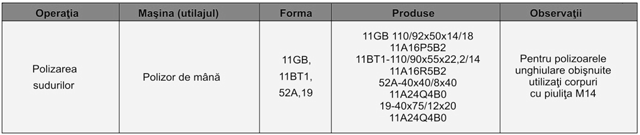

2.2 Welded work pieces grinding

-use 11GB, 11BT1, 52A and 19 shapes grinding wheels

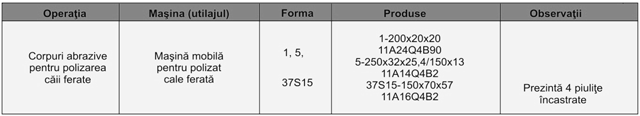

2.3 Rails and railway mechanisms grinding

-use 1, 5 and 37S15 shapes wheels

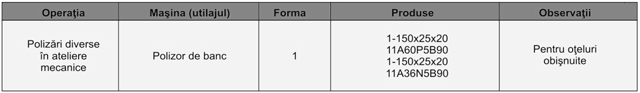

2.4 Grindings in mechanical shops

-use 1 shape grinding wheels

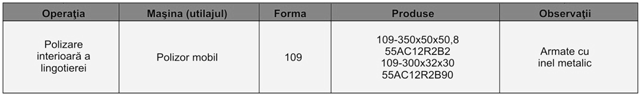

2.5 Ingot mould grinding wheels

-use 109 shape grinding wheels

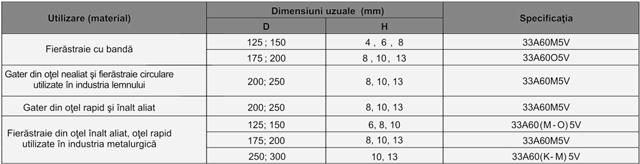

3. Sharpening

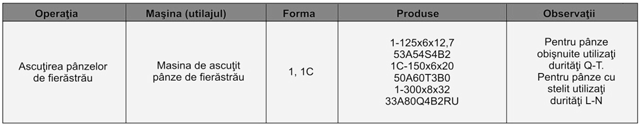

3.1 Saw blade sharpening

-use 1 and 1C shapes grinding wheels

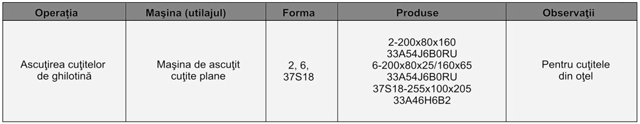

3.2 Guillotine knives sharpening

-use 2, 6 and 37S18 shapes grinding wheels

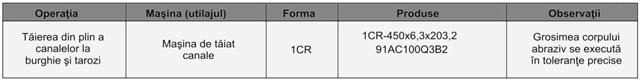

3.3 Cutting of canals and relieving on drils and thread cutters

-use 1CR shape grinding wheels

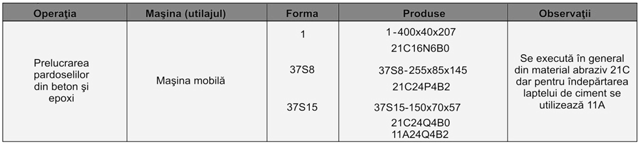

4. Floor grinding

4.1 Floor grinding with mobile machines

-use 1, 37S8 and 37S15 shapes grinding wheels

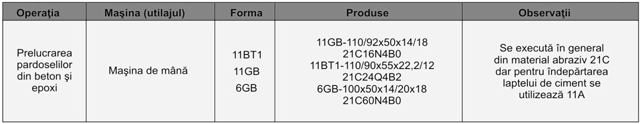

4.2 Floor grinding with hand power tools

-use 11BT1, 11GB1 and 6GB shapes grinding wheels

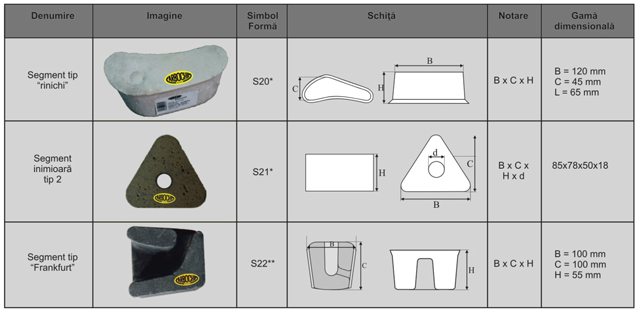

Magnesite bonded grinding wheels - shapes and dimensions

Magnesite bonded grinding wheels are products with mineral bond and that are used for processing heat-sensitive materials. Their main applications are:

- file processing

- stainless steel knives processing

- frame saw sides processing

- processing of concrete, composite and ornamental surfaces using segments

- thick spring ends processing

- equipping husking and grinding machines in the food industry

Magnesite bonded grinding wheels are suitable for wet grinding processes. The maximum peripheral speed permissible for magnesite bonded grinding wheels is 25 m/s for diameters up to 1000 mm and 16 m/s for higher diameters.

Shapes and dimensions

Other shapes and dimensions can be manufactured on customers request

Other shapes and dimensions can be manufactured on customers request

Elastic bonded grinding wheels - shapes and dimensions

Elastic bonded grinding wheels are shaped products made of abrasive grains included in polyurethane, epoxy or polyester bond.

By polishing with this type of grinding wheels there are obtained very good qualities of processed surfaces due to the bond matrix elasticity.

Applications are very divers from polishing to precise rectifying, finishing and super-finishing. An important operation is centerless grinding with leading and finishing grinding wheels.

Maximum peripheral work speed for elastic bonded wheels is 35m/s.

Other shapes and simensions can be manufactured on customers request.

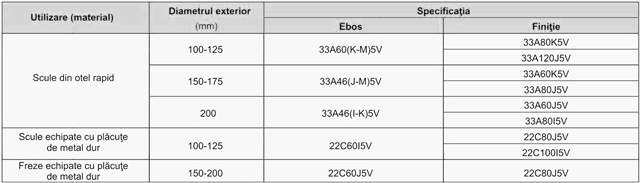

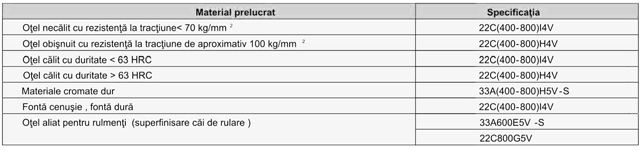

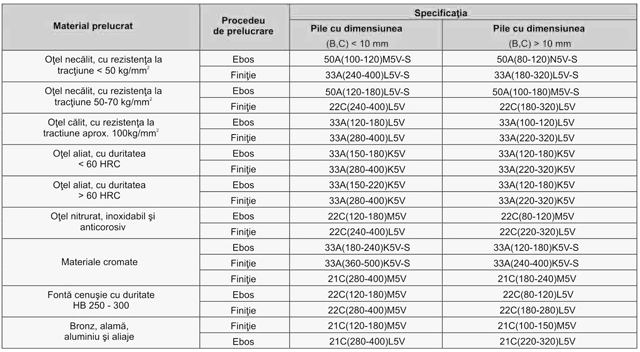

Elastic bonded grinding wheels - general recommendations

Carbochim's elastic bonded grinding wheels general recommendations

Safety rules

According to the SR EN 12413 standard , the following requirements must be observed in order to ensure the safe use of grinding wheels employed in a rotation movement:

-the user must verify the integrity of grinding wheel by means of a visual inspection. The use is forbidden if cracks or other mechanical defects are detected.

-the user must handle the grinding wheels with care, taking into account the fact that they are fragile products.Grinding wheels must not be dropped or hit.

It is forbidden to roll the grinding wheels on any surface with the exception of special rubber surfaces.

-the user must ensure that the revolution or peripheral speed of the machine on which the grinding wheel is mounted does not exceed the revolution or maximum peripheral speed specified on the grinding wheels.

Do not exceed the maximum peripheral speed specified on the grinding wheel!

-the user must verify the sound produced by ceramic bonded grinding wheels as follows: hang on the grinding wheel and hit it with a plastic or wooden hammer in two locations placed symmetrically with respect to the vertical axis. The resulting sound must be crystalline and similar for both strikes. If the sound is stuffy or hollow, the grinding wheel may be cracked and must be verified by a trial speed according to the standard.

-prior to mounting the grinding wheel, the user must ensure that the machine on which it is mounted is in functioning condition and all the safety elements (shields (fenders), electric limiters, emergency stop systems) are in function.

-when mounting the grinding wheels on rectifying machines, the user must observe the following conditions: the cardboard flanges supplied with the grinding wheel must be inserted between the machine's flanges and the grinding wheel.The width of the cardboard lining must cover the entire flange tightening ring surface and exceed its circumference by 1-2 mm.

After mounting, the ensemble consisting of the metallic flange and the grinding wheel must be compulsory balanced using the device provided by the rectifying machine belongings.

-the cardboard flanges delivered with the grinding wheel must be obligatory used when mounting it on fixed grinders.

The grinding wheel must be mounted with the lighter side (indicated by a radial line or arrow on its flat surface) facing downwards.

-the user must establish a grinding and cooling regime that does not overstrain the grinding wheels. The grinding wheels must be properly selected for its use. If there are special requirements related to the rectified materials, grinding regime or cooling liquids, recommendations regarding the proper specification must be requested from the producer.

-the user must ensure proper ventilation of the work place in order to eliminate dust, vapors and smoke resulting from the grinding process.The waste resulting from the use of grinding wheels does not affect the environment, is not toxic and is biodegradable.

Grinding wheels can be stored or buried under normal conditions. They may be used as filler in the production of bricks and refractory concrete.